Top 3 Logistics Questions For Pole Base Projects

IN THIS VIDEO

If you're considering switching to precast site lighting foundations, you probably have some questions about logistics!

We've put together the top 3 logistics questions contractors ask us when they're getting started with Pole Base on their site lighting projects. Here they are:

- How are precast bases delivered?

- Where are they put on site?

- How much space do they take up on site during installation?

HOW ARE POLE BASE PRECAST UNITS DELIVERED?

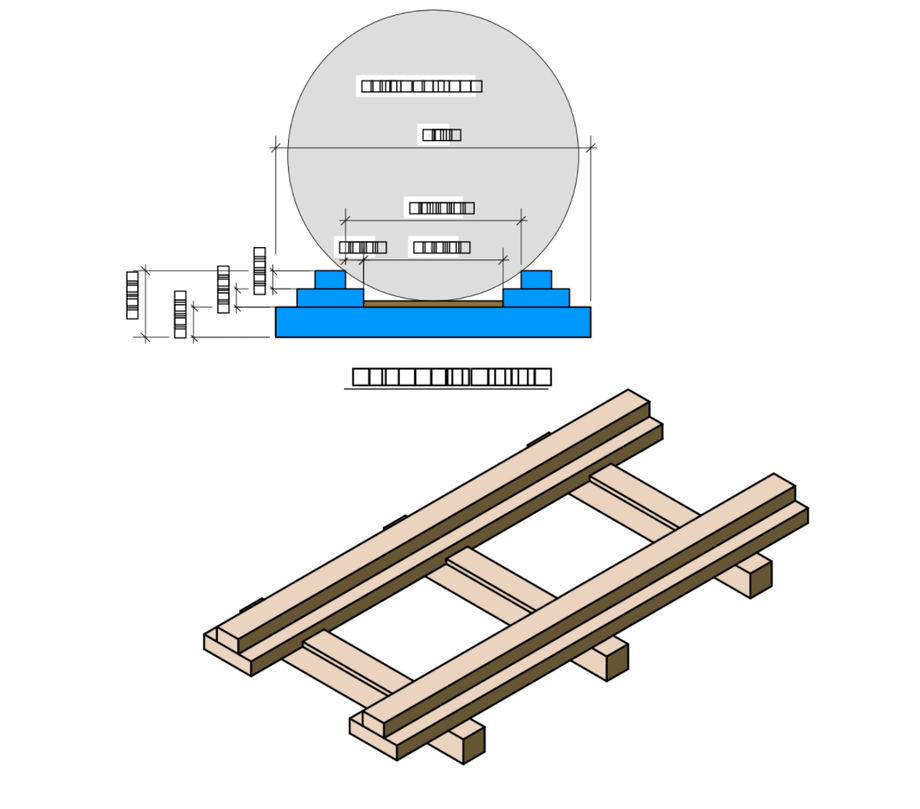

These bases are usually delivered on a flatbed trailer, with each base palletized individually. Contractors on site can simply use a forked piece of equipment to unload the bases from the truck and move the bases around on site.

The pallet specification depends on the region and manufacturer and can accommodate multiple diameters depending on the pallet. Find out what the pallets are like in your area by contacting your local Pole Base manufacturer.

WHERE ARE THE PRECAST UNITS PUT ON SITE?

Usually the bases are unloaded one at a time and are taken to one of two places:

- A staging area

- Directly to the point of installation

The advantage of a staging area where all of the bases can be stored is that they will be out of the way until the crews are ready to install the bases. The contractors can then install when they are ready instead of having to schedule mixers and crews to arrive on site and hope rain doesn't stop the installation because alternative installation procedures use cardboard tubes that deteriorate in wet conditions.

The second place contractors usually take bases is directly to the location where they are going to be installed. Usually this is done when contractors are expecting to install these bases on the same day they are delivered, such as the West Branch Streetscape Project. Since the bases are already cured, poles can be mounted the same day!

In some cases, however, the bases aren't stored on site at all! Some Pole Base manufacturers have access to boom trucks that can lift and set these units for contractors.

An example would be the Parkway Meadows Project. The local Pole Base Manufacturer Brutsche Concrete Products produced and helped to install the bases with their boom truck. In cases like this, if the contractors can auger the hole before the boom truck arrives, the Pole Base manufacturer can set the bases in place for a small fee. Be sure to ask your local Pole Base manufacturer if they have a boom truck available. You can find your local manufacturer here.

HOW MUCH SPACE DO POLE BASE UNITS TAKE UP ON SITE DURING INSTALLATION?

The beauty of using precast is that you don't need crew trucks rolling around on site with cardboard tubes, complete rebar cages, and conduit segments ready to set materials down at each location. You don't even need space for a mixer on site to pour the bases! You just need enough space for the equipment to pick up and install the unit (which is often there to auger the hole anyway) as well as the space immediately surrounding the unit itself. This is a HUGE advantage on tight streetscape projects where contractors have limited capacity to shut down lanes of traffic.

So, the next time you're looking into a project with tight spatial requirements, why not give Pole Base a try?

Let's work together and change the world in concrete ways. Get a quote on your next project here.

Or - are you interested in providing Pole Base precast options in your area? Learn what it takes to become a Pole Base manufacturer here!